- Cnc simulator how to#

- Cnc simulator serial#

- Cnc simulator manual#

- Cnc simulator verification#

- Cnc simulator software#

Cnc simulator manual#

Process-orientated conversational programmingįor students advancing to a smaller job shop or tool room, user-friendly MANUAL GUIDE i conversational programming simplifies and enhances their productivity.

Cnc simulator software#

Features such as FANUC’s dual-screen display are standard features, so with additional PC software instructors can replicate the screen of the simulator on a PC, via the Ethernet connection for instructor-led classes on a projector. Students can perform operations and programming exercises away from the machine and then simply take the program to the machine. with provision for final view in 3D using OpenGL.

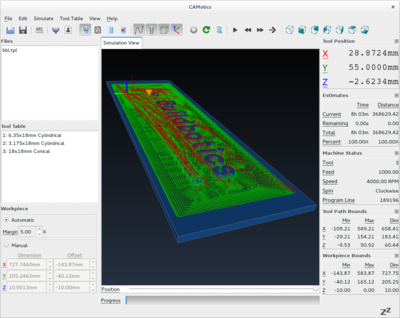

The basis of the three-dimensional simulation model is a. program SSCNC Simulator is designed both for students and for experienced professionals in the field of setting and programming CNC machine tools. A software simulator of a numerical control (CNC) lathe is an educational methodological development intended for basic familiarization of novice machine building specialists with the principles of programming parts turning operations using standard G/M code (Fanuc syntax, System A). program SSCNC Simulator 7.1.2 includes milling and turning groups of machines CNC.

Cnc simulator serial#

Cnc simulator how to#

Simple configurations make it easy to learn how to operate and edit data on a modern FANUC control. CNC GUIDE fits to a classroom situation making both educational and industrial training easily implementable and resulting in better trained staff.

Based on the FANUC 0iF platform, the simulator will allow you at power on to switch between milling and turning configurations to teach programming, navigation, and operation on the world’s most popular CNC control. The CNC Simulation rack is highly efficient way to impart the significant knowledge of complete CNC system - with practical movement of motors as an. The simulation emulates the CNC exactly, meaning that programs can be written, tested and optimized on the PC bringing productivity gains by working off the machine. NOTE: The Mazak Custom Macro option may have to be purchased from Mazak.The FANUC CNC simulator is a perfect addition to the classroom and an essential component to gain maximum exposure to FANUC CNC controls when actual machine time is limited. More M codes can be added to Predator Virtual CNC as needed. NOTE: Mazak M-codes are specific to the Mazak CNC machine. Retract to R Plane or Feed per Revolution - Lathe Retract to Initial Plane or Feed per Minute - Lathe Hole Cycle - Mill or Groove Cycle - Lathe Supported Mazak G-codes G-codeĬancel Scaling - Mill or Set Absolute Zero - Lathe NOTE: Mazatrol conversational is not supported with Predator Virtual CNC. Support for specific Mazak G-codes and M-codes can be adjusted within every Predator Reverse Post Processor. Not all Mazak G-codes are available for all Mazak models and M-codes will vary with each machine.

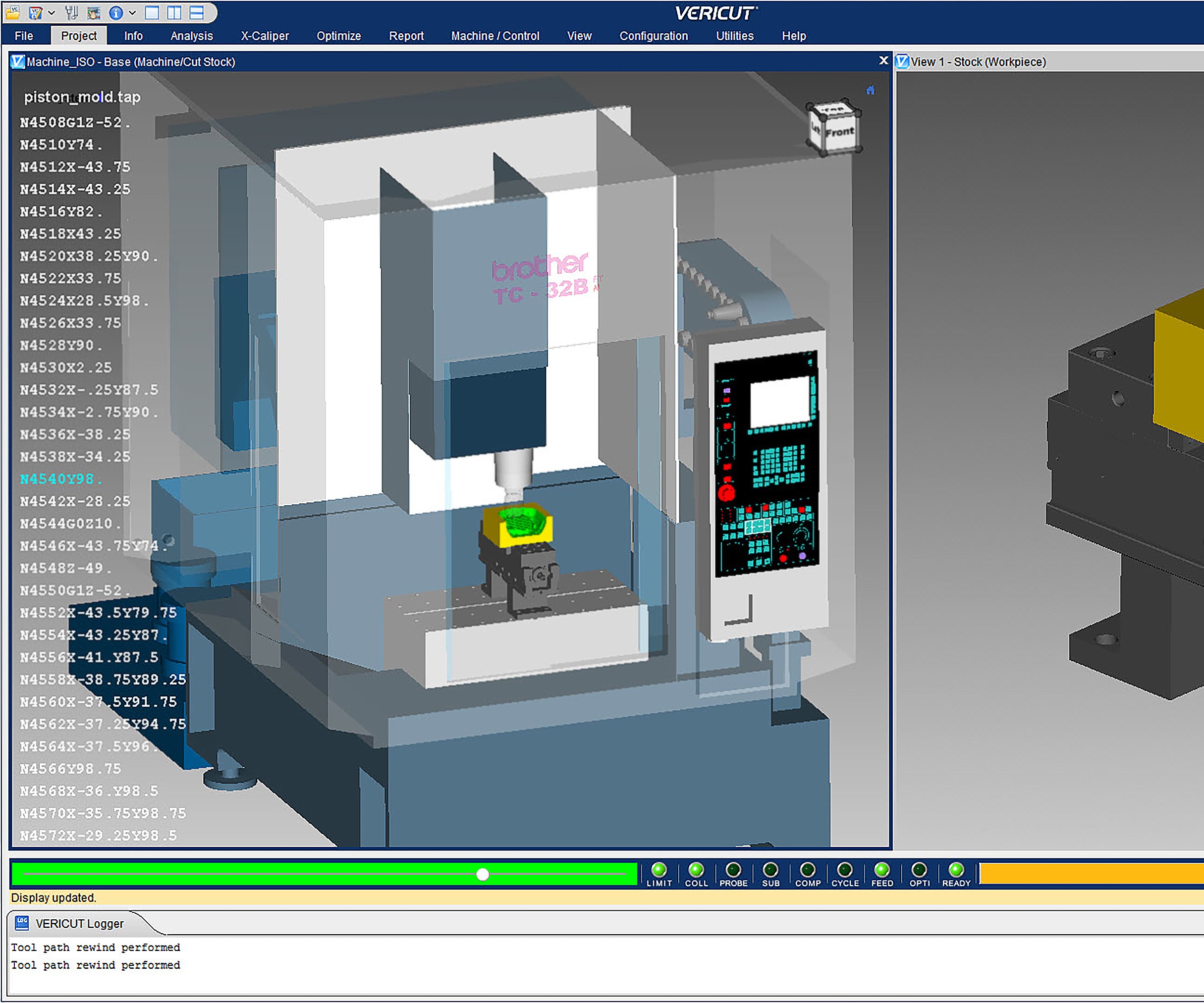

Predator Virtual CNC includes support for all major Mazak G-codes and M-codes standard. Within Predator Virtual CNC, maximize the performance and capabilities of each Mazak CNC model and ensure that the proper part gets machined each time.

Cnc simulator verification#

Predator Virtual CNC provides complete G-code based 3D CNC verification and machine simulation support for all Mazak CNC models. Mazak EIA CNC support with Predator Virtual CNC Software Predator Virtual CNC™ for Mazak CNCs 3D Machine Simulation, verification and backplotting for 2-5 Axis Mazak CNC based Mills, Lathes, Mill/Turns, Lasers, Waterjets and Routers

0 kommentar(er)

0 kommentar(er)